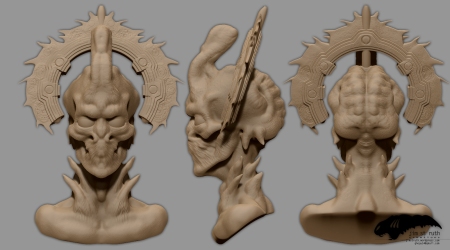

This is my latest full-sized creature bust project which, as always will end up being mould and then cast in resin, painted and set up with glowing eyes. I’m really excited about this sculpt, and it’s coming together very nicely.

The concept was done in a couple of hours in ZBrush, which was then rendered in the front, side and rear views, sized up in Illustrator and then printed out for scale, and taped to a shelf at the rear of my work area so that I could work with full-sized references.

I then started work with a polystyrene foam base, and a core column made from the same material to provide stability and support, with the base in mind to use as a convenient surface to mould on when it’s ready. I knew this was going to get pretty heavy as I worked on it, so picking it up and shifting it around isn’t something that I want to do. For convenience sake, the base was set up a lazy Susan.

The bust sculpt was then built up in Monster Clay medium-grade, turning as I added clay, and then leaving to cool; building up a lot of Monster Clay in one go can sag when it’s still warm. After getting the general silhouette right (checked by shifting the lazy Susan in front of each of the printed references), I cut the end off a broom handle and set it into the top of the skull. This would be the mount for the halo crown.

I then took down the reference images, to allow myself the freedom to develop the piece without being tied down to the original concept. Some of the details changed; replacing the shoulder ‘tentacles’ with the masses pictured below at the front and back around the base of the neck.

After completing the overall forms, and doing some of the detailing, I tried out some skin textures, before moving onto the crown – the detail of the symmetry will come later on.

As this is going to have to be moulded in several distinct pieces, it was time to think about how the moulding would occur. The mould will be a two-part silicone mould, covering the left and right halves, with a two part resin mother mould for stability over the top. This means that the crown will have to be sculpted and moulded separately, in addition to the skull ‘tentacles’, two of which are set behind either ear hole. When the pieces are cast, I need to fit them all together and for the seams to be hidden in a natural manner… so that’s why I’ve started on the crown.

A sized template was printed and cut, then traced onto 5cm polystyrene foam. It was then cut out with a foam cutter, a hole cut into the center, and one end of the sawn-off broom handle slotted into place. The first pic shows the test fit, which is positioned higher than in the concept. She’s now 71cm high (!), the largest piece that I’ve worked on, and extremely imposing on the desk!

The halo was then removed, covered in clay, and I’ve started to lay out the forms. Again, I’ve changed the design into something that I think feels better. The final two shots are of the unfinished halo fitted into place so I can check the size, developing silhouette and overall feel.

This is going to cost a couple of hundred pounds to mould and cast, so I need to make sure that everything’s as perfect for moulding as it can be. When the sculpting is done, I’ll take my time with the mould, so I don’t waste the money. I need to get it right first time. Eventually, I’ll stick The Mother on Etsy as casts for sale, after my own cast is painted and wired up with her glowing eyes. I might add some more LEDs in the holes around the neck too, if the tests look good.

She’s beautiful and scary and, like the other ‘night light’ busts I’ve done, will look really creepy in our hallway. The sculpting work should be basically done this month, and I’ll mould and cast the crown, the two pairs of skull ‘tentacles’ too. Then I’ll fit these into the main bust and finish the sculpting there to get the seams right, before removing the cast pieces, moulding and casting the main body… though that might have to wait until June; so I can afford to mould such a large piece, and to give me time to check my thinking on how the moulding for the main part of the bust will actually pan out.

Thanks for looking!

Jim.

The pictures don’t quite do the piece justice. It’s far more exciting to look at in real life! That’s partly due to my lack of decent photography skills, and also due to my phone’s camera.

The pictures don’t quite do the piece justice. It’s far more exciting to look at in real life! That’s partly due to my lack of decent photography skills, and also due to my phone’s camera.